Our 160 acre intertidal farm on Tomales Bay is home to several different types of oysters we grow and harvest. The Pacific oyster, our Sweetwater, is the star of our show and harvested year round. Our other oyster varieties are a labor of love really, harvested seasonally and as ‘special occasion’, to provide you with a unique sampling of the simplest pleasures in life.

Hog Island Sweetwaters

Hog Island Sweetwaters. Our original oyster and the star of our show: A rich, and as the name suggests, sweet-tasting Pacific Oyster with a slightly smoky finish. Plump meat sits in a beautifully shaped, deep-cupped, fluted shell that is the result of rack and bag farming techniques.

Hog Island Highwaters

Let’s hear it for Hog Island Highwaters! Our first-ever batch of Pacific Oysters to be planted, grown, AND harvested at our Humboldt Bay Farm. Tide tumbled high in the mudflats, our Highwaters pack a merroir that’s totally Humboldt Bay: a light brine, seaweed umami, and an earthy finish.

Hog Island Atlantics

An East Coaster out West. Hog Island is one of only two west coast oyster farms raising this classic East coast oyster variety. Harvested seasonally, and on special occasions, Hog Island Atlantics have smooth, oblong shells, delicate meat and crisp minerality. One of our favorite ‘summer time’ oysters.

Hog Island Kumamoto

Good things come in small packages. Kumamotos are a Pacific oyster originating from the Kumamoto Prefecture, Kyushu, Japan. Cultivated on the West Coast since the late 1940s, these oysters take an average of two to three years to reach market size at, 1-1.5 inches. Each tiny shell packs in big flavor: Buttery, succulent meat with a lingering essence of cucumber and melon.

French Hog

Native to Western Europe, the most famous market name for this oyster is the Belon. Increasingly this has become a very rare oyster to cultivate worldwide. At Hog Island, we are working to preserve and, ultimately, build our seed supply. This oyster is bold and unique. Flat, round shells deliver a full-body, meaty oyster with a ‘copper-like’ palate.

Earthquake Bays

The new kid on the block. Earthquakes get their name from the San Andreas fault, which formed Tomales Bay. Grown in rigid mesh bags that gently tumble in the tide, Earthquake’s constant motion gives them an extra deep cup with a plump, meaty texture and a slightly sweet, mild brine finish.

Hog Island Olympia

A true California native and the West Coast’s only indigenous species of oyster. We’re proud to be part of the restoration efforts to renew the local Olympia oyster population. Tiny but mighty in flavor; bright with salinity and umami, with a very light coppery finish.

Manila Clams

This small, hard shell clam with exquisite markings from nature is a treat to steam open or enjoy raw. Chefs love them for their presentation in a dish, and nearly everyone loves their easy flavors: delicate, sweet and just ever so slightly, nutty.

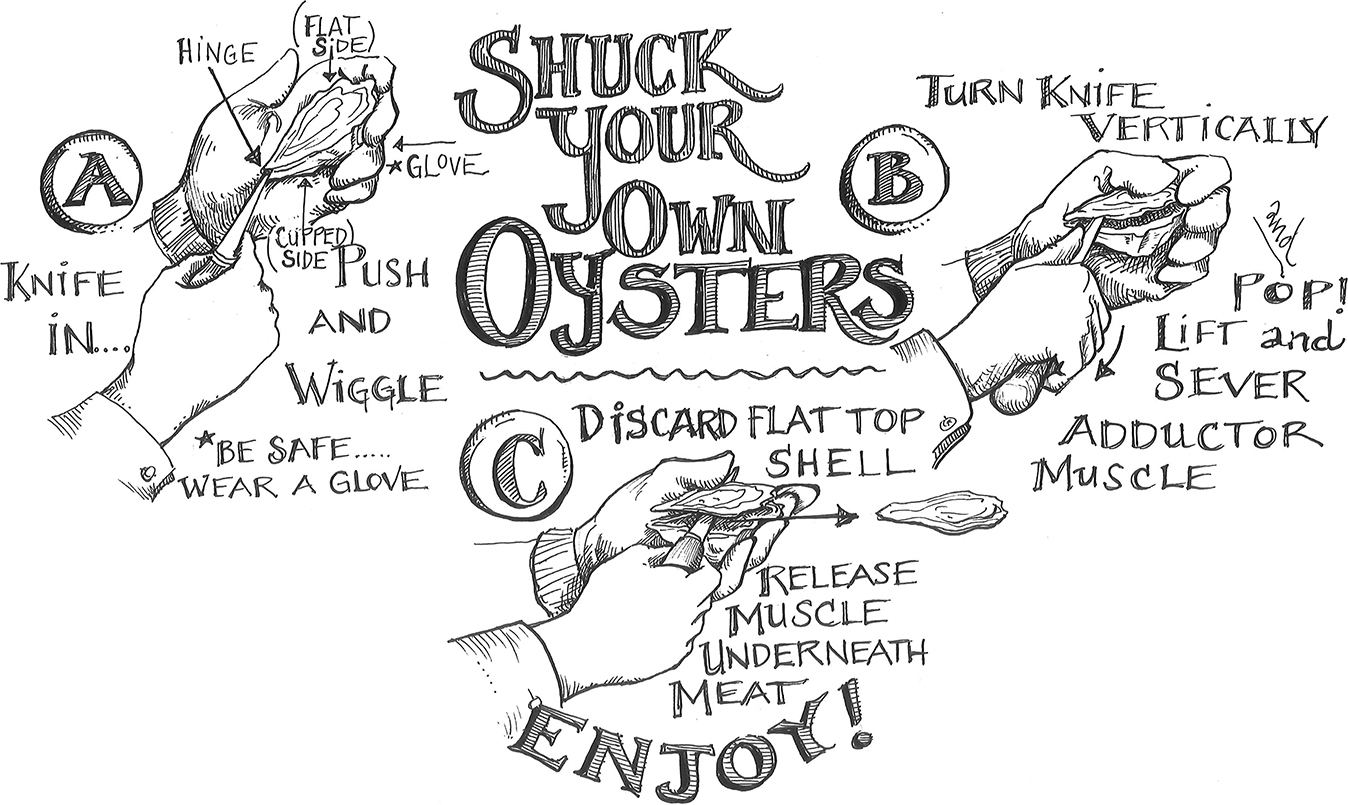

How To Shuck An Oyster

There are many ways that people open oysters to get to the good stuff inside. We shuck in a way that keeps the meat intact and presents the oyster perfectly, ready to slurp straight from the shell.

An Oyster’s Journey

From Seed—The Hatchery

Oyster farmers worldwide rely on an abundance of healthy, productive seed to keep shellfish farms and the aquaculture industry thriving and sustainable. Raising seed in a hatchery setting protects young oysters from predators and environmental stresses, greatly increasing their survival success when transferred out to the bay for grow out.

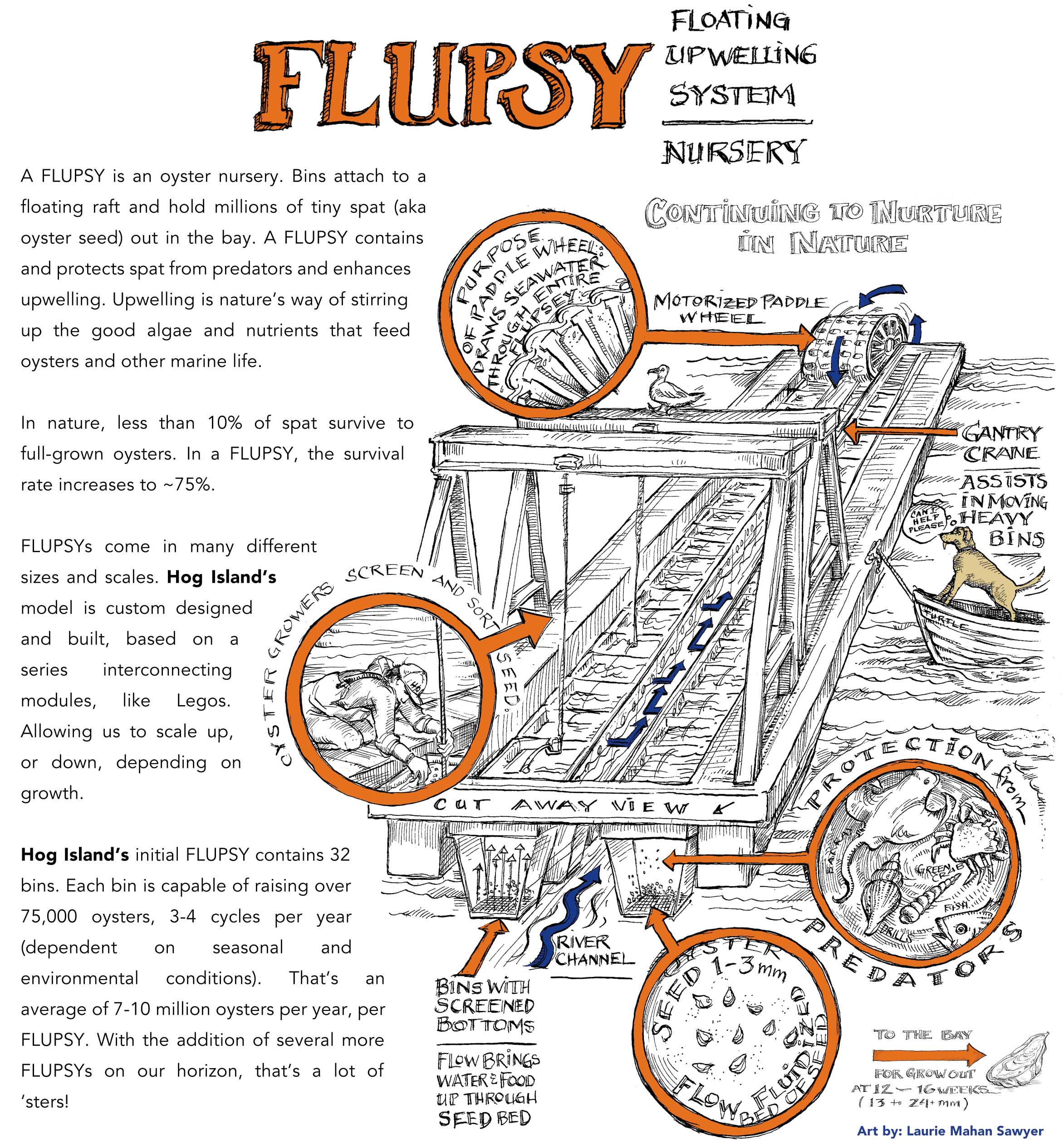

The Nursery

Hog Island Oyster’s nursery in Humboldt Bay is a custom-designed, state of the art FLUPSY (Floating Upweller System). When spat reach approximately 1-3 mm in size, they are transferred to our nursery, FLUPSY. A FLUPSY contains and protects young oysters and enhances the natural upwelling of nutrients and phytoplankton in the ecosystem that oysters feed on. Our nursery team tend to the oysters daily to monitor their health, condition, and growth.

Grow Out

When the oyster seed reaches approximately ¾ inch, they are transferred from FLUPSY to grow out leases in the bay. In Tomales Bay, our standard growing method is a ‘rack and bag’ system adapted from French aquaculture. Oysters are planted by the hundreds in reusable mesh bags fastened to rebar racks which elevate the oysters from the bay floor. Being elevated from the bay floor allows the best tidal flow to surround the shellfish so they can easily feast on natural phytoplankton and nutrients in the water column. Our oysters are raised in intertidal zones of the bay where they spend part of their lives out of the water, exposed to air. Depending on the species of oyster, they will spend anywhere from 12 months to three years here, filtering up to fifty gallons of seawater per day as they feed on natural minerals and nutrients provided by mother nature.

Tipping & Flipping

This is a term near and dear to most oyster farmers. While we do not feed or put any fertilizers in the water, farming single oysters is still a very hands-on practice. Our farm crew is out in the bay on a regular basis, literally flipping, shaking and tipping our bags of oysters to improve their shape and condition, which improves their overall quality. Flipping racks, which hold close to a thousand oysters per rack, is hard, physical work. The rewards are beautiful, high-quality oysters and a great ‘office’ environment.

Harvesting

Harvest days may begin at 4:00 am in the morning or 8:00 pm at night. It all depends on the tides. When the tides are just right (just above knee height), our crew hauls hundreds of bags of oysters deemed ready for market onto our harvest boat. The haul is moved from the boat to our farm where for the next several hours our crew hand sorts the shellfish for size, condition, and quality. Only the best oysters are bagged up for market, the rest are put back into the bay to continue to grow. It’s another labor-intensive, hands-on process, but one that ensures that only our best oysters head to market.

To Plate—Live Wet Storage

After the best oysters are bagged up for market, we treat them to a 24-hour soak in our seawater “oyster spa”. Designed by Hog Island co-founder, Terry Sawyer, (who was a marine aquarist in a former life), our live wet storage is a system of tanks designed to hold living oysters in a UV filtered, chilled seawater setting very similar to their natural surroundings. Think large aquariums.

Resting time in the tanks ensures every single Hog Island Oyster served to you is consistently fresh, clean, and of the highest quality.